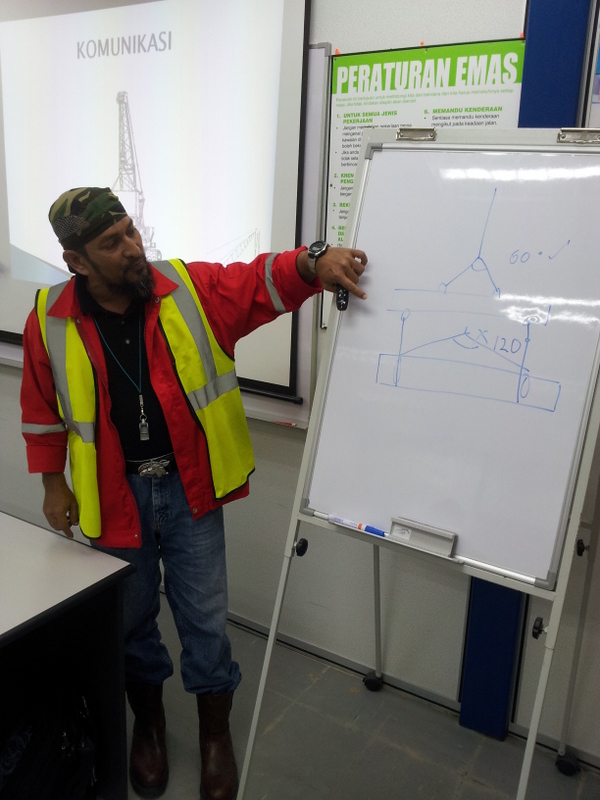

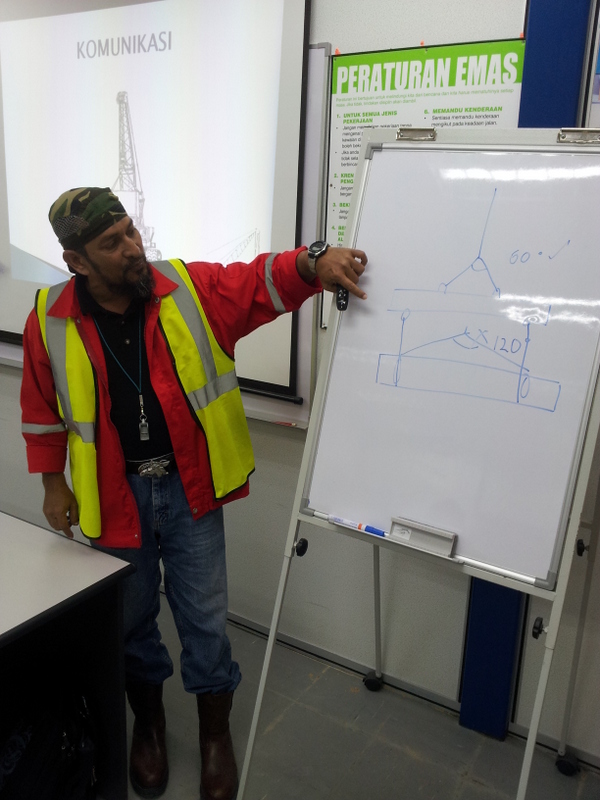

Name : Iskandar Gunasegaran Bin Manirajan

Nationality : Malaysian

Date of Birth : 19-05-1979

Institut Teknologi Kejuruteraan Midas, Kulim, Kedah.Academic Qualification

- Sek. Men. St Patrik, Kulim Kedah;

- Sek. Ren. Keb. Sri Kulim Kedah;

Course/Training Attended

1) Diploma In Electronic Engineering

2) Industrial Electronics Training

(Conducted by: Institut Teknologi Midas)

3) Basic Tubular Scaffolding Courses

(Conducted by: SDU Sdn. Bhd.)

- Intermediate And Advance Scaffolding Course

(ASIA Skill Training Sdn. Bhd);

- Scaffolding Inspector

(Conducted by: Dt Training and Consultancy);

- Sea Survival: Helicopter Underwater Emergency Training

(Conducted by: SCQU Offshore Safety Sdn. Bhd.);

- Safety Induction (Green Card) Course

(Conducted by: SDU Sdn. Bhd.).

- Boset Opito sea survival course.

Technical Qualification

1) Dosh Register No. Spp (A)/Pp/021/2003;

– Basic Scaffolding (Tubular)

2) Dosh Register No. Spp (T)/Pp/031/2004;

-Intermediate And Advance Scaffolding

-Scaffolding Inspector

Summary of Working Experience

1) Monitoring and Supervising of Scaffolding Erection;

2) Inspection of scaffolding during and after erection for safety and fit for use;

3) Provides daily guidance and acts as subject matter expert for HSE policies and procedures;

4) Independently analyzes situations and data to determine best course of action;

5) Planning for schedule, manpower, material, facilities and safety for erection of scaffolding.

6) Coordinate administrative, logistics and operational work, as well as liaise with Clients’ project personnel to prepare, execute and fulfill project deliverables and schedules as related to Site Supervisor work.

Work Experiences

2012 – Current TOTAL E & P Myanmar (TEPM)

Position : Scaffolding Inspector/Supervisor & Site Supervisor

Project : Cilegon Yard, Jakarta office in Indonesia (for onshore mission)

and TEPM Yadana Field in Myanmar

(for Offshore works)

Responsibilities :

1) Inspection material including safety procedure wise at Gunanusa yard for yadana project.

2) Development and enforce safety procedures and requirements, inspect and report unsafe incidents, conduct safety toll box discussion and training to the operation and maintenance team members on job site safety and preparation of system safety procedure to be applied in Yadana project.

3) Preparing daily report for CSR.

Project Description

The Yadana gas field is located in the Andaman Sea, approximately 60 kilometers offshore the nearest landfall in Myanmar. This major energy resource contains more than 5,3 trillion cubic feet (150 billion cubic meters) of natural gas, with an expected field life of 30 years. In 2007, production averaged more than 21.5 million cubic meters per day.

The offshore complex comprises:

- Two well platforms (WP1 and WP2 on the diagram) with seven wells tied into each.

- A puction platform.

- A living quarters platform.

- A medium compression platform (MCP), installed in December 2007, as provided for in the initial project development plan, enabling production to be maintained and the contractual gas delivery obligations to be respected.

2010 – 2012 Technip Singapore Pte Ltd

Position : Scaffolding Inspector/Supervisor & Site Supervisor

Project : EPCIC of Phase 1 Gas Full Field Development of Turkmenistan Block 1- Petronas OGT Gas Terminal.

Responsibilities :

1) Assist and advises the all foremen’s in preparation of scaffolding aspects inclusive but not limited to methods, procedures etc.

2) Establishment of scope of works related to scaffolding.

3) Liaise with the production team and scaffolding team regarding better production and smooth going aspects.

4) Estimation of material and Preparation of request according to work pressure of project.

5) Administration and monitoring of team members including time cards, de employment of members, work schedules etc.

6) Responsible for the implementation of the Scafftag system and ensuring that all scaffolding erected complied with standard.

7) Co-ordinating the scaffold workforce and material requirements on the onshore platform.

8) Estimation and preparation of Extra claims for variation of scope and contract and their subsequent submittal to clients for extra works payments.

9) Responsible for the workers’ welfare and worker-related administrative matters

10) Responsible for all project-related matters, including resolution of project and technical issues, attending regular site meetings, and ensure accuracy and timely submission of all project-related documents

Project Description

The construction of Phase 1 at the Block 1 in Turkmenistan including mechanical works, site preparation, civil works, buildings works on EPC basis, E&I works, tanks, heavy lifting, insulation and commissioning. The scope of work also includes a pipe line from offshore to Turkmenistan Block 1 (onshore).

2007 – 2009 Malaysia Marine and Heavy Engineering, Pasir Gudang

Position : Scaffolding Inspector/Supervisor & Site Supervisor

Project : Gumusut Project (KAKAP)

Responsibilities :

1) Monitoring and Supervising of Scaffolding Erection for hull structure, E&I and commissioning;

2) Inspection of scaffolding during and after erection for safety and fit for use to workplace;

3) Provides direction and assistance with the implementation of core Health, Safety Environmental (HSE) issues on site operations trains, monitor and workers and interfaces with training department to improve skill levels for managing HSE initiatives.

4) Worked on various types of scaffolding for painting, Independent Tide Scaffold, Property System scaffold, Tower Scaffold, Hanging Scaffold.

5) To conduct toolbox meeting daily to all personnel onsite and to supervise all issues brought up by supervisor as to relevant environment and work status.

6) To inspect scaffolding in a 7 days intervals according to legislative requirement (Factories & Machinery Act 1967, BOWEC 1986) & British Standard 5973.

7) To guide & consult scaffolding erectors on the correct type, design & duty of scaffold that is required at site.

8) Delegate/assign tasks to workers as appropriate and supervise to ensure compliance with stipulated procedures, methods of statement and safety requirements

9) Report and assist in the investigation of safety violations, dangerous occurrences and accidents, where necessary

2005 – 2007 ISHI Power Sdn. Bhd

Position : Scaffolding Inspector/Supervisor & Site Supervisor

Project : 3x700mw Coal Fired Power Plant In Tg Bin, Serkat Pontian, Johor Darul Ta’zim

Responsibilities :

1) To ensure all sites and work place safety compliances;

2) Conduct workplace inspection, monthly audit and report;

3) Record keeping for all documentations pertaining to Safety and Health matters;

4) To keep and maintain all safety equipment, PPE and etc;

5) To plan & implement safety programme;

6) Establish operational procedures and programs in line with Occupational Safety & Health and Environment objectives & coordinate HSSE activities;

7) Promote Industrial safety among employees by conducting safety tool box talk, campaigns and individual counselling;

8) Maintain reports of accidents for management action and investigate industrial accidents to determine causes of the accidents;

9) Liaise with Statutory Authorities of the accidents;

10) Experiences on Power Plant shut-down, steam-blowing;

11) In charge on scaffolding for Boiler and Boiler Auxiliary;

12) Erection alteration and dismantling;

13) Lowering materials;

14) Inspection of scaffold;

15) Compliance with statutory regulations.

16) Undertake additional tasks and responsibilities as and when required or instructed

2004 – 2005 KLCC Project Bhd

Position : Scaffolding Inspector/ Supervisor & Site Supervisor

Project : Luxury Condo

Client : IJM Construction Sdn. Bhd.

Responsibilities :

1) In charge on scaffolding for two Block of Luxury Condo;

2) Monitoring and Supervising of Scaffolding Erection;

3) Inspection of scaffolding during and after erection for safety and fit for use to workplace;

4) Ensure workplace is complying with Health, Safety Environmental (HSE) criteria.

5) Issuing of safety Tags after inspection of scaffolding i.e. Green, Red, Yellow Tags

2003 – 2004 RM Leopard

Position : Safety / Scaffolding Supervisor & Site Supervisor

Project : 1. Petronas Fertilize Kedah

- Plant Modification Project for Equator Eng. Sdn. Bhd. And Mitsubishi Heavy Industries (M) Sdn. Bhd.;

- Natal Fertilize Kedah

- Plant Construction Project for Algotech Sdn. Bhd. (Main Contractor);

- Petronas Fertilize Kedah

- Plant Maintenance for Petronas (Owner);

- TNB Jana Manjung Sdn. Bhd. Perak-Plant Maintenance

- Istan (M) Sdn. Bhd.

Responsibilities :

1) Monitoring and Supervising of Scaffolding Erection and Dismantling for Boiler Auxiliary, Power Plant & Oil and Gas Industries.

2) Chain and Anchor pattern, FPSO installation and commissioning, Jackets, Jack Up and Gravity Bases, Flexible Flow and Control Lines, Salvage, Sub Sea Installation, Cameron Tools, Piling, Heavy Lift (dual crane 3,500 tonne), Oil and Gas Rig Installation, Hook-up, Wellhead maintenance, Pigging.

2002 – 2003 Penang Shipbuilding & Construction Sdn. Bhd.

Position : Scaffolder

Project : Offshore-Cakerawala

Responsibilities :

1) Involved in painting, electrical works and rigging for Cakerawala modular platform.

2000 – 2002 Syarikat Thean CHYE

Position : Assistant Scaffolder

Project : Onshore – Cakerawala Gas Field Development Project (Ctoc)

Client : Technip Geo Production (M) Sdn. Bhd.;

Project : Resak Compression Module Project

Client : Petronas Carigali Sdn. Bhd

Responsibilities :

1) Involved in painting, electrical works and rigging (Onshore works).

Oct 97 – Apr 98 Tongkah Electronics (Bukit Minyak, Prai)

Position : Technician (Industrial Training)

Responsibilities :

1) As a line leader to ensure all output works orderly.

Material Standard And Care

- Factories and Machinery (building, operation and work of Engineering Construction) Safety Regulations 1986 – 10 ACT & 1967 – 139 ACT);

- Specification for timber scaffold boards BS-2482;

- Specification for timber ladder steps, trestle and light weight scaffold BS 2037;

- Specification for metal scaffolding BS 1139 / EN 74;

- Access and working scaffolds equipment access BS5973;

- Temporary install suspended scaffolds access equipment BS 5974

- N.B Equivalent to British Standard are acceptable always provided the certification is available.

Structure Design

- Due to the environment which onshore installation operate it is essential that intricate and load bearing scaffolder are designated prior to erection;

- All scaffolding 40 meters in heights shall have proper scaffolder design drawings and be endorsed by a professional structural engineering prior to allowing the scaffold to be erected for on shore scaffold only:

A copy or the approval scaffold design drawing shall be:

a) Made available at the work site for inspection;

b) Forward to DOSH for endorsement.

Factory And Machinery 1967 (Act 139)

- Building operations and valve of engineering construction (Safety Regulations 1986 ) – Pg 237;

- Part X (10) pg 375 / SCAFFOLD Regulation 72;

- Part X (10) pg 384 / SCAFFOLD Regulation 91;

- Standard BS 1139 / JIS TK 51 / DIN;

- Part X (10) pg 376 / Design / Drawing Scaffold Approved Regulation.

Regulation 75

- Design drawings-inspection approved

- (40 meter metal tube scaffold / design draw seed approved);

- 15 meter all frame (Scaffold / design draw seed approved);

- Safety factor not less than 4;

- Inspection of scaffold Regulation 85;

- Inspected by designated person several inspections (a competent person employed or approved by the employers to carry out supervisor / inspection).